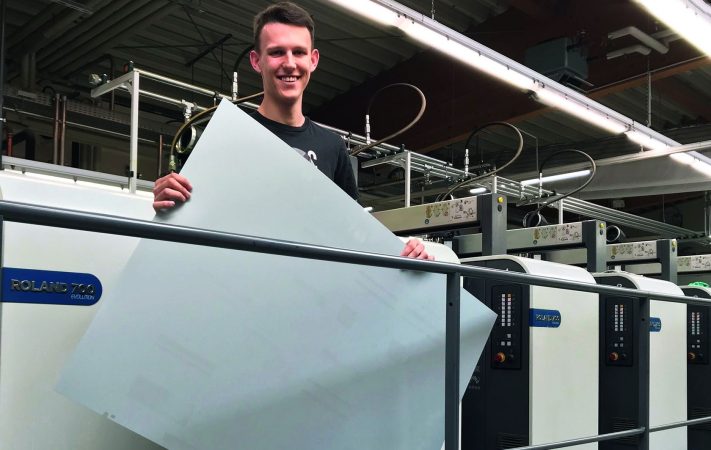

Wals-Siezenheim, Salzburg, Austria

offset5020 Druckerei und Verlag GesmbH

As a short-run specialist with a focus on sustainability, offset5020 has reaped the rewards of process-free platemaking

Company

Family-owned, full-service commercial print shop based near Salzburg that specializes in offset and digital printing

Challenge

Increase capacity to handle shorter but more frequent print runs, while also addressing environmental concerns

Kodak Solution

SONORA Process Free Plates

Introduction

In today's demanding industry the pressure on printers to offer ever shorter runs is constant. offset5020 Druckerei und Verlag GesmbH is no exception. This successful Austrian firm needed the capacity to meet rising demand for small volume, fast turnaround, highly customized print – delivered with minimum fuss and setup time. KODAK SONORA Process Free Plates provided the perfect solution.

The Business Need

Employing 85 people from their base near Salzburg, offset5020 specializes in offset and digital printing, with a portfolio that includes business cards, brochures, mailshots, posters and books, as well as a booming web-to-print business delivered through their online portal.

Low volumes and short runs are central to their business, but with a rising plate consumption approaching 40,000 square meters a year, the company was looking to upgrade its operations to handle this part of its print business more quickly and efficiently.

Having been awarded the prestigious Austrian Ecolabel, as well as FSC and PEFC certification and “carbon neutral” status, offset5020 also wanted to reinforce its commitment to sustainable, environmentally friendly print.

The Kodak Solution

Using Kodak plates since 2002 and the KODAK SONORA XP Process Free Plate since mid-2014, offset5020 upgraded to the SONORA X Plate in 2019, deployed on two five-color sheetfed offset presses with a coater in 70 x 102 cm format, alongside a smaller 50 x 35 cm press providing extra offset capacity.

A 200 lpi screen is standard, while either a halftone screen with 275 lpi or an FM screen is used to meet special image quality and resolution requirements.

The SONORA Plate's run capacity of up to 200,000 in sheetfed offset was more than enough to cope with the company's maximum print run, which rarely exceeds more than 80,000 copies.

The Outcome

Since introducing Kodak's process free plate technology, offset5020 has been able to eliminate all expenditure on processing chemistry.

They are using 700,000L less water and 4800 kWh less electricity per year, with savings of around €3500 in chemistry disposal costs and €4000 in cleanup and maintenance of the plate processor.

They have also found that their prepress process and production is more stable, thanks to SONORA Process Free Plate's superior plate robustness and improved scratch resistance.

Contact Us

Contact a Kodak representative to learn how our products and solutions can help grow your business.